What Is Medical Device Prototyping ?

Medical Device Prototyping

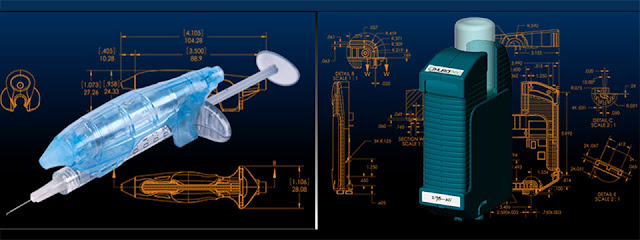

Medical device prototyping is rudimentary to

coming up with a design to medical products and the production process. Coming

up with advanced models of products in medical technology gives you the chance

to analyze or evaluate the idea and task of additional enhancements.

Lately, medical devices have become an

increasingly growing sector. The improvements seen in materials, design and

technologies have raised the likelihood of finding a superior quick fix for

those medical complications whose redress was, up until now, inconceivable. A

broad scope of new answers is applicable varying from new items to new

commodities, tools and methods.

Doctors have found out how the most recent

approaches to engineering aid their job by making surgery and treatment

procedures more accessible than it was during the early days. Because of this

reason, medical equipment are now the top subject matter of mechanical and

academic importance in fields such as prototypes, design and production.

To come up with a quality device, one must

follow the right procedures. Fruitful prototyping requires proper

understanding of the objective of the prototypes, finding out who is meant to

use the device, fundamentals of the prototypes and choosing the right

manufacturing procedures for each part.

Prototyping of medical equipment

Prototyping is an essential weapon in the

market exploration and product development procedures. An efficient model can

swiftly transmit design ideas to a final user, company administration, or a

possible venture capitalist.

Prototyping gives room for marketing to

witness the feedback of other people to ratify or nullify the product concept.

It is an effective tool used to decide the application of the equipment by

watching how people relate to it. The prototype can put to the test the

engineering usefulness of a design idea.

Categories of prototypes

The various types of prototypes that can be used

during the production of medical devices include:

●

Presentation prototypes- This is a form of

resemblance prototype which is inapplicable. It can be used in the purchasing

shares from Marketing to send an idea to the user and get some response about

it.

●

Workability prototypes- This one can be used

to substantiate fresh design ideas and clear-cut device responsibilities. Such

prototypes can resemble the appearance of respective modules, do not often

simulate the original object or even the capacity of the end product. This type

of prototype can apprise product development over the course of a particular

design to take and accommodate itself to quick redundancies to make swift

progress.

●

Functional prototypes- These type of

prototypes come in a self-sufficient package and supply the engineering team

with an apparatus to examine design necessities. Such prototypes are also used

in the repetitive design series where the unit is analyzed, and design

amendments are made to attain the design blueprint.

●

Production prototypes- This type of prototype

is used to produce products that will make their way to the market. Different

parts can be put together with prototype manufacturing, and small quantity

assembling procedures can be used appropriately. The model is the last emphasis

that is heading for production. The number of parts produced should be enough

for the authentication of a particular model, where the fundamentals can be

examined to guarantee conformity to the stipulations.

Methods of prototyping

Once you decide on the intention and aim for

the prototype, the means of production can be resolved. The procedures for

manufacturing procedures may consist of a sample part and production cost,

starting time, completion, structural precision, and firmness of the items. The

various methods include:

3D prototyping

It is the most approved procedure of

prototyping. The design is made using computer-aided design, and a

three-dimensional data file is created. The created file is used in the

production of a prototype, where a couple of ejection methods like selective

laser sintering, selective laser melting, fused deposition modeling,

stereolithography and digital light processing.

Normal machining

Machining is a well-entrenched procedure of

prototyping. It gives room for the application of a couple of materials which

include many plastics and metals. This method of prototyping has the benefits

of high accuracy levels and minimal manufacturing expenses. However, the price

of the piece can be high because of the job content.

Casting

In this procedure, a design of the piece is

first built to shape a part using a special joining liquid popularly known as

resin. The design is traditionally made through machining process or 3D

prototyping. A sculpt made and separated into two equal parts of the design

using malleable silicone or conglomerate material. The binding material is then

drained into the sculptor make it harder.

The disadvantage that comes with this

procedure is that it can only produce solid pieces with a limited mold life.

The process is steady in precision, production, and cost of pieces.

Molding

When you are molding a piece, a small cavity

should be formed on the area to be fabricated and integrated into a sculpture

frame. The most convenient molding procedures include compression, injection,

rotational and blow molding. Sculpting prototypes have extended production

times than fabricating, and higher manufacturing costs. The benefits you get to

enjoy with molding include quality surface finishing, steady dimensions, reduced

prices and the manufacturing of top quality pieces.

Thermoforming

Thermoforming makes good use of a plastic

sheet which is heated and set up on a double structural sculpt with the use of

free space to extend the plastic material into the sculpture where it is given

room to cool down and maintain its last shape of completion.

The main advantage of this procedure is the

fact that it can bring into existence pieces with various widths on the wall by

fluctuating the sheet stockpile. The production times and manufacturing prices

are ordinarily reduced than molding.

The detriments that come with using this

prototyping procedure include low spatial precision, restrictions on matters

related to arithmetics and surface completions. There are persistent needs for

after completing all the activities.

Conclusion

Medical device companies have been relying on traditional methods over the past years which has proved to be ineffective.Prototyping in the production of medical equipment has seen the creation of most devices that have been useful in the health sector. There is no better production method for medical device companies than prototyping.

Conclusion

Medical device companies have been relying on traditional methods over the past years which has proved to be ineffective.Prototyping in the production of medical equipment has seen the creation of most devices that have been useful in the health sector. There is no better production method for medical device companies than prototyping.

Comments

Post a Comment