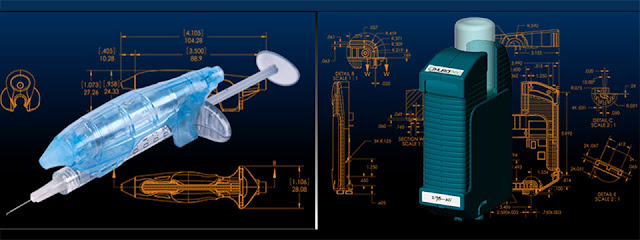

Prototype Machining Services

What is Prototype Machining Services? Prototype machining services are industrial services offered to clients and these machinations are normally drilling, turning, welding, and threading to name a few. The sizes vary and so, too, do the diameters. Clients are able to order custom-made parts which are small in numbers. Therefore, these are not enough for low-volume manufacturing; neither are they enough for manufacturing on a regular basis. Prototype machining services are for innovative clients who have an affinity for designing and need custom-made parts to achieve different effects or styles. The main purpose of these custom-made parts is to experiment with new concepts to achieve the preferred product or perhaps to upgrade a now obsolete prototype. It is very simple to make minor modifications to the current part; and this may be done by adding to the product lifespan, lengthening or shortening a part, varying the thread pitch of a bolt and changing the product