How to Choose Machining Methods for Precision Surgical Robots?

In

recent years, robot manufacturing technology has become more and more mature,

and there are more and more use cases in industrial and medical scenarios,

their commercialization process has been accelerated. When it comes to

robots, there are always some hot topics to discuss. From the cute child robot

to the practical family sweeping robot, we can see more and more robots in

daily life. According to Yole Development data, the robot market will grow from

$27 billion to $46 billion between 2015 and 2021, with a compound annual growth

rate of 9.4%. Today we're going learn about surgical robots in the medical

field.

According

to statistics, the number of medical robot surgeries increased from 25,000 in

2005 to 650,000 in 2016; In 2014, surgical machines accounted for more than 60

percent of the world's medical robots, accounting for the largest proportion;

By January 2016, the annual revenue of the global medical robot industry has

reached $7.47 billion, and the compound growth rate is expected to be stable at

15.4% in the next five years. By 2020, the scale of the global medical robot

industry is expected to reach $11.4 billion.

A

surgical robot is a combination of instruments. It usually consists of an

endoscope (probe), surgical instruments such as knives and scissors, tiny

cameras and joysticks. For now, with the continuous development of the robot

industry, medical and surgical robots have gradually been highly concerned by

the society due to their accuracy, reliability, repeatability and

cost-effectiveness. It is generally believed that surgical robots have the

following five advantages.

One is

surgical instruments with multiple degrees of freedom, making surgery more

dexterous. And the dexterity of surgical robots is based on the following two

points: 1.The tremor filtering system filters out the surgeon's

hand tremors and the motion reduction system proportionately reduces the

surgeon's motion amplitude.

2. Surgical robot simulation manipulator, can simulate human hands to achieve various operations, which is very convenient. It has a very high degree of freedom of movement,Including the arm joint up and down, before and after, left and right movement and manipulator about, rotation, opening and closing, end joint bending and so on,Some can also rotate 360° along the vertical axis and 270° along the horizontal axis, reaching angles that even human hands might not be able to reach.

2. Surgical robot simulation manipulator, can simulate human hands to achieve various operations, which is very convenient. It has a very high degree of freedom of movement,Including the arm joint up and down, before and after, left and right movement and manipulator about, rotation, opening and closing, end joint bending and so on,Some can also rotate 360° along the vertical axis and 270° along the horizontal axis, reaching angles that even human hands might not be able to reach.

Second is to provide doctors with magnified three-dimensional

images, allowing surgery to be done in greater detail. It can enlarge the

operation site by 6 to 10 times, facilitating fine operation, which can provide

real vision for the doctor.

Third,

it has changed the previous mode of operation. Instead of the doctor standing

next to the patient, the doctor now sits in front of the console to relieve the

fatigue of the doctor.

Fourth,

remote surgery can be achieved. We can put robots in remote areas, remote

control by doctors, so that more patients in remote areas can enjoy the

benefits of high-end equipment. (on the other hand, remote surgery can achieve

a highly sterile surgical environment, which can greatly improve the safety of

patients and doctors.)

Fifth, because of its small, flexible operating arm and ability to magnify inside the body, During surgery, doctors can place a robotic arm inside a patient's body instead of their own hands, so doctors can operate on patients with only a small incision. This not only reduces bleeding and the area of exposure to the wound, which reduces the patient's casualty rate, but also reduces the time it takes to complete the operation and the time it takes for the patient to recover.

Fifth, because of its small, flexible operating arm and ability to magnify inside the body, During surgery, doctors can place a robotic arm inside a patient's body instead of their own hands, so doctors can operate on patients with only a small incision. This not only reduces bleeding and the area of exposure to the wound, which reduces the patient's casualty rate, but also reduces the time it takes to complete the operation and the time it takes for the patient to recover.

Robots are regarded as the pearl in the crown of manufacturing

industry, and surgical robots are the commanding heights of technology and

strategy for all countries to fight for. Do you know how the general parts of

surgical robot are manufactured? Yes, due to the characteristics of the

surgical robot industry, many of their parts are processed by CNC machining. Then, we will

briefly introduce the correlation between CNC machining services andsurgical robot parts.

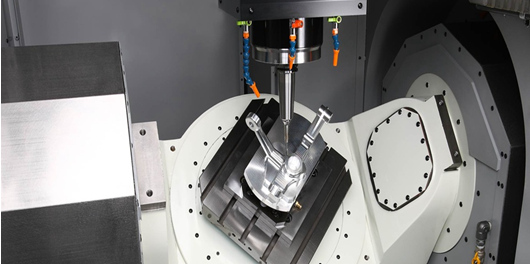

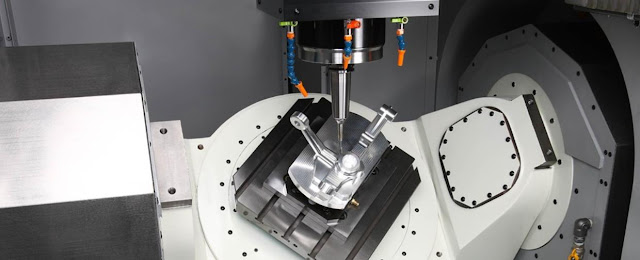

Why is CNC Machining Suitable for the Production of Surgical Robot Parts?(Advantages)

1. High Precision

We

all know that surgical robots, both now and in the future, are expected to

focus more on lightweight materials, precise parts and innovative designs of

dexterous robot structures. CNC machining can meet the requirements

of high precision. In wayken, our continuous 5-axis CNC allows for simultaneous

movement of all five axes during all machining operations. This unprecedented

versatility provides the high precision necessary to produce parts with complex

'organic' geometries to a level of accuracy unobtainable with any other

technology. Accuracy capable of producing very smooth 'organic' surfaces with

minimal machining marks. Tolerances as close as +/-0.025mm to +/-0.005mm.

2. Customizable

processing

More

advanced surgical robots tend to have more complex mechanical structures, a

surgical robot often has many different mechanical structures, therefore, in

order to build such a complex surgical robot, different parts of the mechanical

structure may need to be customized. And in the booming robotics industry, as

the technology changes very quickly, so even if a surgical robot is produced, a

processing method that can adapt to the continuous updating and iteration of

robots is needed to support the industry to continuously update generation

after generation of stronger surgical robots. Therefore, the fast turnover

of CNC prototype manufacturing is very suitable. CNC's fast

processing cycle and the ability to adjust programming path in a timely and

flexible manner make CNC machining the best choice for surgical

robots.

3. In terms of

quantity requirements

A

sophisticated surgical robot can often cover many types of complex surgery, take

the world's most advanced Da Vinci surgical robot, it currently has around

4,000 to 5,000 units worldwide, but the Da Vinci system has performed five

million operations, it is used almost every 36 seconds. So it's not hard

to see surgical robots don't have to be built in large Numbers, therefore,

compared with mass production, CNC low-volume manufacturing with high

precision and high customization will be more suitable for it. On the other

hand, in order to be safe, the mechanical arm of Da Vinci robot needs to be

replaced regularly and continuously, but the amount of each replacement is usually

very small, so it is suitable for CNC

machining in this aspect.

Concluding

Remarks

In any case, the combination of

medical treatment and robot is becoming more and more obvious, and the

advantages of CNC prototype manufacturing china for medical robot are

also obvious.

Comments

Post a Comment