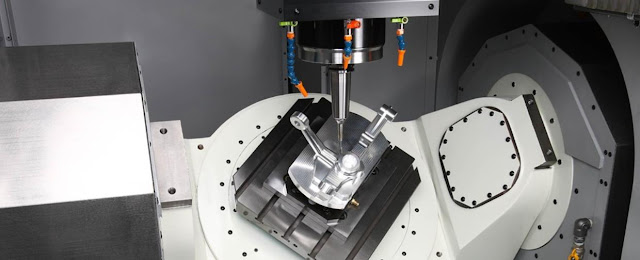

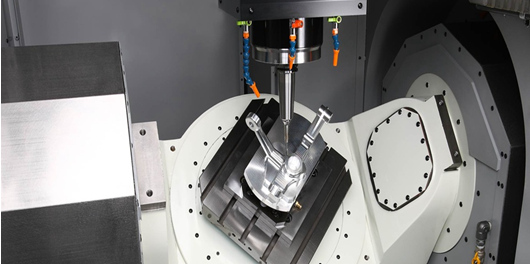

Why We Choose the CNC Milling Services?

Usually, all products that have just been developed or designed need to make a prototype in the rapid manufacturing industry. The prototype is the first step to verify the feasibility of the product, and it is the most direct and effective way to find out the defects, shortcomings, and drawbacks of the designed product, so as to make targeted improvements to the defects until the defects can't be found from individual samples. At this point, we usually also need to conduct a small amount of trial production to find out the batch is not enough to improve. This design is then converted into a physical prototype which is time-saving and also attracts a lot of customers due to its aesthetics as a result of modern rapid prototyping techniques used. The Way a Prototype is Processed 1) 3D Printing The advantage of 3D printing mainly lies in its rapidity, but it is mainly formed by stacking technology, so 3D printing is generally relatively rough and has