Metal Prototyping

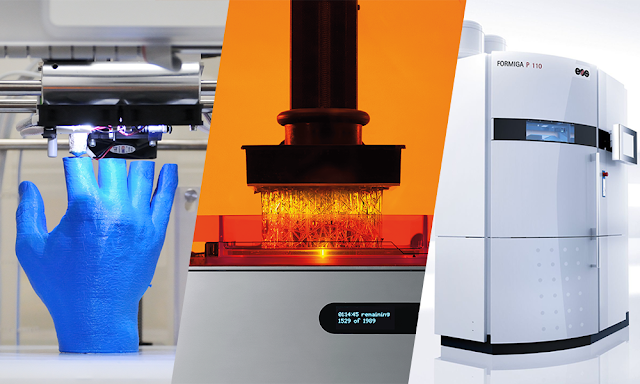

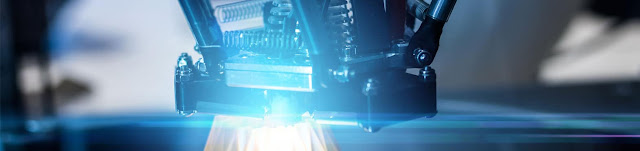

The special of metal prototyping need that motivates the variety of rapid prototyping technologies arises because product designers would like to have a physical model of a new part or product design rather than a computer model or line drawing. The creation of a prototype is an integral step in the design procedure. Available rapid prototyping technologies for metal prototyping can be divided into two basic categories: (1) Material removal processes. (2) Material addition processes. The material removal RP alternative involves machining, primarily milling and drilling, using a dedicated Computer Numerical Control (CNC) machine that is available to the design department on short notice. To use CNC, a part program must be prepared from the CAD model The starting material is often a solid block of wax, which is very easy to machine, and the part and chips can be melted and resolidified for reuse when the current prototype is no longer needed. Other starting materials ca