How CNC Machine Shop Apply in Prototype Manufacturing

What is CNC machining technology?

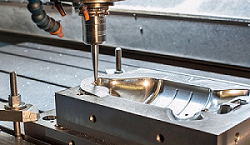

Nowadays many prototype companies possessa CNC machine shop, especially CNC milling. Then what is CNC machining

technology?

Computer Numerical control (CNC) is the

use of computers to automatically control processing tools and 3D printers. CNC

machine tools process a piece of material (metal, wood, plastic, ceramic or

composite) in accordance with coded program instructions, without the need for

manual operation. Therefore, compared with traditional machine tools, CNC

machine tools have better machining precision in CNC machine metal and plastic. In modern CNC systems, the design

of mechanical parts and their manufacturing processes are highly automated. The

mechanical dimensions of the part are defined using CAD software and then

converted to manufacturing instructions using computer aided manufacturing

(CAM) software.

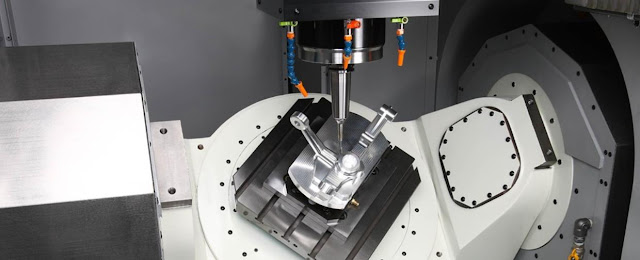

There are several commonly used CNC

machines: CNC Milling machine, CNC turning, CNC plasma cutter, among which CNC

milling machine can be divided into 3-axis, 4-axis, 5-axis milling machines.

Different axis can process different direction of CNC parts. They make a huge

sense on nowadays’ prototype manufacturing.

What is

Precision Machining?

Precision machining is an evolving

manufacturing sector that affects our daily lives. Therefore, it is a key

contributor to this field today. But what is precision machining?

Precision machining is a process that

removes excess raw material from the work-piece while maintaining tight

tolerances to produce the finished product. In a word, this means processing

large pieces of material into more precise parts so that they meet very precise

specifications.

What is Quality

Precision Machining?

Quality precision machining requires

very specific drawings that can be produced in accordance with CAD or CAM

programs such as AutoCAD and TurboCAD. The software can help produce complex,

3D charts or overviews needed to make tools, machines or objects. These

blueprints must be followed in great detail to ensure that the product maintains

its integrity. Although most precision machining companies use some form of

CAD/CAM program, they still use hand-drawn sketches often during the initial

stages of design.

The second factor to be precision

machining is using CNC equipment. Precision mechanics use a variety of

materials such as glass, bronze, plastic, graphite, steel and other metals. A

variety of precision machining tools and techniques will be used according to

the size of the project and the materials involved. Therefore, operators must be

proficient in these different processes and equipment and have experience. They

can use any combination of grinders, drill presses, lathes, saws, CNC milling

machines, and even high-speed robots to get CNC parts done. With the high

precision involved, CNC machine tools are often used to make sure that the

finished product meets the exact dimensions.

The aerospace industry may use high

speed machining, while the woodworking tool manufacturing industry may use

photochemical etching and milling processes. The output of a run, or the

specific number of any particular item, can be thousands or just a few.

Precision machining usually requires the programming of numerical control

equipment, which means that they are computer numerically controlled. CNC

equipment allows precise dimensions to be followed throughout the operation of

the product.

How CNC Machine Shop Apply in Prototype Manufacturing

Today's industry is growing at an

alarming rate. In order to meet the needs of today's customers, keeping up with

the trend or going ahead of the trend is critical to your business. Here are 7

advantages of using CNC precision machining in the prototype manufacturing.

1.

Lower Errors.

By using a CNC machining, once the

correct specifications are entered, the automated precision machining process

takes over. Compared to manual machining, the chance of error is extremely low.

When you outsource this work, you don't have to hire the highly skilled

employees who can help run these machines.

2.

Reducing material waste

Because the core concept of finishing is

subtraction, there is a huge potential for material waste from start to finish

on a product. CNC precision machining helps reduce material loss due to human

error. The contract company may also purchase the bulk of the materials you

need to work and transfer the money you have saved.

3.

Consistent product quality

Through the precision machining of CNC

machine tools, consistent output can be obtained again and again. Consistently

producing high quality CNC machining metal and plastic parts can enhance

customer confidence and increase brand awareness.

4.

Improving Workflows

When considering how to manage

opportunity costs, the key is that engineers' time and skills are spent on

actual product development rather than minor design changes. Companies that

offer contract precision machining services can often assist with minor

modifications during the prototyping process to meet design or industry

standards.

5.

Shorten turnaround time

There is an opportunity to improve your

existing plant workflow (you can use internal precision machines if you can

afford machine investment and skilled workforce), or use contract processing

services. Contract companies have experience with this type of work and have

the right systems to get the job done as efficiently as possible.

1.

Faster production cycles

Modern CNC machining brings your

products to market faster, giving you an advantage over facilities that still

use the old methods. You may be more flexible due to changes in industry rules

or customer requirements.

7. Simplified Prototype Testing

1) Precision machining offers your

business an opportunity to explore smaller niche markets with potentially high

returns. Precision CNC machining can allow for a flexible product development

phase because the niche opportunities are deterministic. If there is demand in

the market, processing can be transferred to full-size production mode.

2) Precision machining also allows

prototypes to have features rather than more concepts/design prototypes.

Functional prototypes are more likely to inspire investor confidence than

conceptual prototypes.

Comments

Post a Comment