Available additive manufacturing materials for production

What is additive manufacturing?

Additive Manufacturing (AM),known as 3D printing, combines

computer-aided design, material processing and molding technology, based on

digital model files, and uses specialized metal materials, non-metallic

materials, and medical biomaterials through software and numerical control

systems.According to extrusion, sintering, melting, photo-curing, spraying,

etc.,layer by layer, to create a manufacturing technology for physical objects.

Compared with the traditional processing mode of raw material removal-cutting

and assembly, it is a kind of "bottom-up" manufacturing method by

material accumulation, from scratch. This has made it possible to manufacture

complex structural parts that were previously constrained by traditional

manufacturing methods and that could not be realized.

Additive manufacturing of metal materials

Early

additive manufacturing techniques were primarily prototyped for rapid response

to product designs, including resins and plastics. As the market demand

continues to increase, additive manufacturing technology can not only meet the

appearance requirements, but must also gradually shift to the manufacturing

functional parts, thereby increasing the research on metal materials.

1. Titanium

alloy

Titanium alloy has the characteristics of

high strength, good corrosion resistance and excellent high temperature

mechanical properties. It is the strongest and lightest material in 3D

printing. It is used in a process called direct metal laser sintering. This

metal is mainly used in high-tech fields such as space exploration, aviation

and medical fields. However, high processing costs and long lead times limit

the scope of application. In particular, the aerospace and biomedical fields

with customized requirements highlight the drawbacks of traditional processing

methods. Titanium alloy is the first alloy material to be widely studied and

applied in additive manufacturing technology.

Main features:

It provides greater complexity and

resolution in the design.

It provides precise design for industrial

designers.

It has average surface roughness.

Titanium is also biocompatible and

corrosion resistant.

2. Steel

Steel

is the largest branch of alloy material. The diversity of steel composition,

morphology and preparation process has made it an extraordinary place in

traditional manufacturing. In the history of additive manufacturing technology,

steel is also an important material widely used in forming research, and can be

subdivided into three categories: stainless steel, high-strength steel and die

steel. 304 and 316 austenitic stainless steel powders (and their low carbon

steel grades) are the first stainless steel materials developed for laser

forming research and are now the typical processing materials in the additive

manufacturing market due to the strength and detail of stainless steel.

Important, so it is ideal for miniature models, bolts and key chains.

Main

features:

Steel

can be heat treated to increase strength and hardness.

It

has good high strength applications.

High

corrosion resistance.

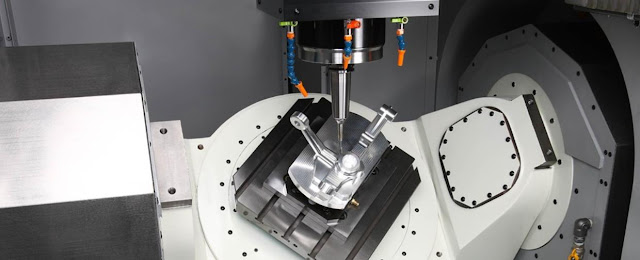

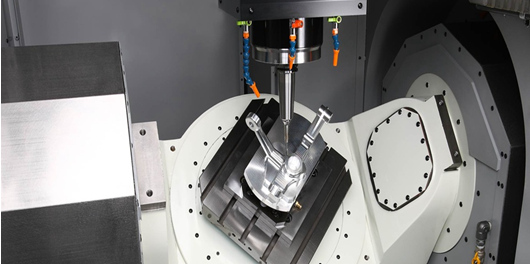

3. Aluminum

alloy

Aluminum

alloy has low melting point, relatively small temperature gradient in the rapid

melting process, and the formed parts are not easy to deform and crack, which

is generally applicable to SLS and SLM processes.When aluminum is used, the

fine details can be up to 25 microns and the wall thickness can be up to 50

microns.Parts usually have a textured matt surface that distinguishes them from

conventional milling aluminum parts.Because of its light weight, 3d-printed

aluminum is used in car and racing parts.

Main

features:

Excellent

physical, chemical and mechanical properties.

It

has good corrosion resistance.

Additive manufacturing of polymer materials

1.

ABS

Polymer wire is mainly suitable for FDM

technology. Currently, it mainly includes PLA, ABS, PC, PPSF, PETG, etc.ABS is

the most commonly used thermoplastic engineering plastics in FDM due to its

excellent insulation, corrosion resistance and low temperature resistance.ABS

has the advantages of easy surface coloring, high impact resistance, high

strength and good toughness.To create a 3D printed object using ABS, the

filament must be heated to a relatively high temperature of 230-250 c. The high

melting point of ABS makes the object relatively warped and crack

resistant.This makes ABS an ideal choice for making certain cases and other

end-use components.ABS is also used for rapid machining and creating conceptual

models.But there are some shortcomings: the products are easy to shrink

deformation, surface prone to layer peeling and warping phenomenon.

2. Photosensitive resin

Photosensitive resin is a kind of polymer

material which can be cured by uv irradiation at a certain wavelength.In recent

years, additive manufacturing technology is booming, and photosensitive resin

is gradually entering the mass market.Photosensitive resin has been widely used

in SLA, DLP, 3DP and other forming technologies.Compared with the general

curing materials, the photosensitive resin has good surface drying performance,

the surface of the molding is smooth and clean, the product resolution is high,

the detail display is excellent, the quality even exceeds the injection molding

products.These outstanding advantages make it the preferred material for

high-end and artistic 3D printing products.However, at present, the cost of

photosensitive resin is still on the high side, and the mechanical strength,

heat resistance and weather resistance are mostly lower than the engineering

plastic consumables used in FDM, which affects the application range of

materials to a certain extent.

3.Nylon

High molecular powder is widely used in SLS

molding due to its low sintering energy, simple sintering process and good

prototype quality.SLS molding requires polymer powder to have the

characteristics of low agglomeration temperature, shrinking shrinkage, low

internal stress, high strength and good fluidity.At present, the common polymer

powder is polystyrene, nylon, nylon and glass microsphere mixture,

polycarbonate, polypropylene, wax powder and so on.Nylon is a full-density

material, the manufactured workpiece has high strength, elasticity and high

tolerance, suitable for tight fitting and various functional tests, such as fan

housing under high temperature operation test, impact and fall test.It also has

the advantages of heat resistance, low friction coefficient and wear

resistance.The disadvantage is large water absorption, affect the size

stability and electrical properties, fiber reinforced resin can reduce the

water absorption rate, so that it can work at high temperature, high humidity.

Concluding Remarks

With

the development of additive manufacturing, increasing research and development

of raw materials is a topic. Especially in the research and development and

application of new materials, according to the characteristics of additive

manufacturing, combined with the market application of various requirements,

vigorously develop new raw materials, additive manufacturing materials will

continue to improve the quality of the development direction.

Comments

Post a Comment