Why We Choose the CNC Milling Services?

Usually,

all products that have just been developed or designed need to make a prototype

in the rapid manufacturing industry.

The prototype is the first step to verify the feasibility of the product, and

it is the most direct and effective way to find out the defects, shortcomings, and drawbacks of the designed product, so as to make targeted improvements to

the defects until the defects can't be found from individual samples. At this

point, we usually also need to conduct a small amount of trial production to find

out the batch is not enough to improve. This design is then converted into a

physical prototype which is time-saving and also attracts a lot of customers

due to its aesthetics as a result of modern rapid prototyping techniques used.

The Way a Prototype is Processed

1)

3D

Printing

The

advantage of 3D printing mainly lies in its rapidity, but it is mainly formed

by stacking technology, so 3D printing is generally relatively rough and has

strict requirements on the product wall thickness. For example, it cannot be

produced if the wall thickness is too thin.

Moreover,

there are some limitations to the materials and properties of 3D printing.

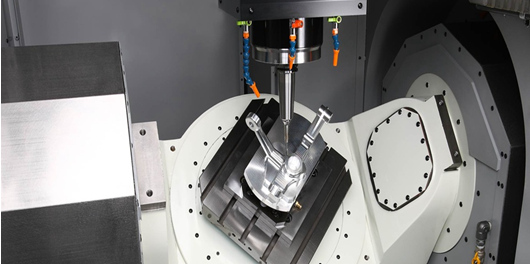

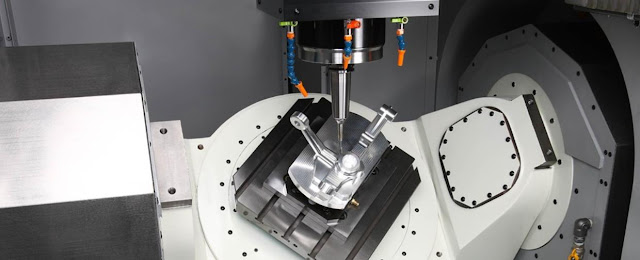

2) CNC Machining Services

The

advantage of CNC prototype is that it can reflect the information expressed in

the drawings very accurately, and the surface quality of CNC prototype is high,

especially after finishing the surface spraying and silk-screen printing, and

even more brilliant than the products produced after the opening of molds.

Therefore, CNC prototype manufacturing is becoming the mainstream of prototype

manufacturing.

To

sum up, CNC machining has absolute advantages if your prototype needs high

requirements for surface effect, tolerances, and material performance.

Then you may have a new problem, what kind

of the CNC processing services have?

What kind of CNC processing services have?

Numerical

control machine tool, short for Computer control numerical machine tools, is an

automatic machine tool equipped with a program control system. CNC machine

tools to achieve complex, precise, small-batch, multi - varieties of parts

processing is a flexible, efficient automatic machine tool, represents the development direction of modern machine control technology.

There

are many kinds of CNC machining services, according to different methods of CNC

machine tools for classification, if according to the use of technology

classification, commonly used can be divided into CNC lathe services, CNC milling services,

EDM and so on.

The lathe can only process rotary body parts, so not as widely used as a CNC milling machine.

As we all know, CNC milling parts processing advantage is strong adaptability,

flexibility, CNC milling services can be applied to processing contour shape is

particularly complex or difficult to control the size of the parts, such as

mold parts, shell parts, etc. It can process parts that need to be processed by

multiple processes after clamping positioning, which greatly improves the

surface accuracy of CNC milling parts.

However,

due to the limitations of the tool, CNC milling parts will inevitably leave radii

in the direction of the tool processing, and some inverted shape of the tool

cannot be processed. But these two problems can be solved by EDM. In a word, CNC

milling parts are still widely used.

Development history of CNC milling China

The milling machine was first created by

American e. Whitney in 1818. In order to mill the spiral groove of the twist

bit, American J.R. brown created the first universal milling machine in 1862,

which is the prototype of the knee-type milling machine. Planer milling machines

appeared around 1884. In the 1920s, semi-automatic milling machines appeared,

and the work table could complete the automatic conversion of "feed - fast

forward" by using stoppers.

After 1950, the milling machine in the control

system development quickly, the application of digital control greatly improved

the degree of automation of the milling machine. Especially after the 1970s, the

microprocessor digital control system and automatic tool change system in the milling machine has been applied, expanding the milling machine processing

range, improve processing accuracy, and efficiency.

With the increasing mechanization process,

CNC programming began to be widely used in machine tool operations, greatly

releasing the labor force. CNC programmed milling machines will gradually

replace the current manual operation. The demands of employees will be higher

and higher, and of course, the efficiency will be higher and higher.

China's CNC industry cannot be satisfied

with the status quo, should seize the opportunity to continue to develop, and

strive to develop their own first

To advance technology, strengthen

technological innovation and personnel training, improve the comprehensive

service capacity of enterprises, and strive to shorten the gap with developed

countries. We will strive to realize the transformation of CNC machine tool

products from low-end to high-end, from primary product processing to

sophisticated product manufacturing, and realize the transformation from made

in China to create in China, and from a manufacturing power to a manufacturing

power.

After entering the 21st century, such as

computer technology, network technology, and communication technology,

represented by information technology, biotechnology, and new materials

technology is widely used in every field of machinery manufacture, the qualitative leap in the mechanical manufacturing technology, significant

changes have taken place in manufacturing production mode, high technology,

digital, high extremes, greening, the characteristics of high integration and

development prospects.

Why CNC

milling China is so popular in the world

China's

export prototype demand is also growing. Now let's analyze why CNC milling

China is so popular in the world.

1) CNC milling China has developed very well can meet the high precision industry parts demand.

2) CNC milling China due to relatively low

labor costs, the price has an absolute advantage.

Wayken

is a rapid prototyping company in China that you can trust.

Although

compared with some CNC milling shops abroad, we are not advantageous in price.

But in terms of service, we'll give you value for money.

Because

CNC milling shop has some limitations, there are few CNC milling machines to

choose from, which cannot fully meet the needs of customers, and CNC milling

shop will not provide one-stop service, but we have professional personnel

corresponding to your needs and can continue to provide after-sales service

for you so that you can timely deal with any problems.

CNC A milling shop may give you some lower prices, but after-sales service may bring

you more troubles. It may solve your economic difficulties temporarily, but it

will bring you engineering problems that will make you more upset later. I

think our one-stop service can save you these worries.

Comments

Post a Comment