Prototype Machining, the Equipment It Is Used Widely

How much do you know process of prototype machining? How much do you know which machining equipments can produce the right prototypes.

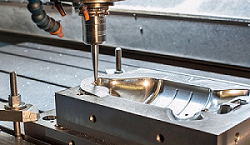

CNC milling

1.

Manual milling and CNC milling

Manual milling is the process of removing a material from a

workpiece by using a rotary tool.. But nowadays, a more advanced milling

machine called CNC milling is gradually replacing manual milling machines, it

brings a variety of benefits for both the machining providers and the clients

that outsource the production of their components.Comparing to manual milling, CNC

milling has benefits of more precision, higher production, less labor and

better uniformity.

CNC milling machines can be controlled not only by computer but

also via manual override. Computer programming allows the machine to make the

precise cuts accordingly but the manual function allows an operator to slow

down or speed up or tweak the process at any time.

2.

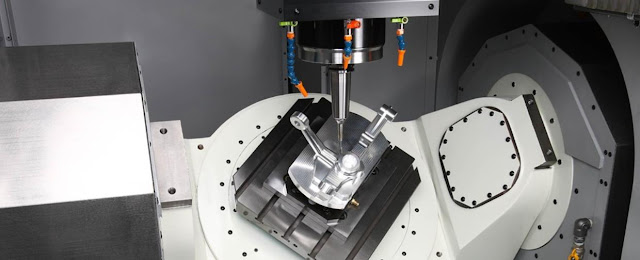

Multi-axis CNC milling

As technology

develops, multi-axis CNC milling machines were invented, this brings more convenience to prototype and

production. There are 3,4,5 axes CNC milling machines.

5-axis machining offers unlimited possibilities for part size and

shape that you can handle efficiently. The term “5-axis” refers to the number

of directions which the cutting tool can move in. On a 5-axis machining center,

the cutting tool can move across the X, Y and Z linear axes as well as rotates

on the A and B axes to approach

the workpiece from each direction. This means that you can machine five faces

of a part in a single setup. Of cause, with such wonderful function,

CNC prototyping cost of process in 5-axis machines will be more

expensive than those in 3 or 4 axis machines.

Turning

Turning is a cutting tool (usually a non-rotating tool) that

describes the machining of a spiral tool path by more or less linear motion

while the workpiece remains rotating.

During the turning process, a variety of operations can be

performed to the workpiece to yield the desired part shape. These

operations may be classified as external or internal. External operations

modify the outer diameter of the workpiece, like turning, facing, grooving, cut-off and thread cutting.

Internal operations modify the inner diameter, such as drilling, boring,

reaming and tapping. These operations are commonly used in lots of machined

parts.

Sinker EDM

Electrical discharge machining (EDM), also known

as spark eroding, spark machining, burning or die

sinking, is a commonly used manufacturing method to obtain a custom shape.

The material is removed from the workpiece by a series of rapid

cycle current discharges between the electrodes separated by a dielectric

liquid and controlled by voltage.

EDM is the most widely used in mold making, tools, molds and other

industries, but it is becoming a common method of manufacturing prototypes and

producing parts, especially in the aerospace, automotive, electronics and other

industries with relatively low production volumes.

Electrostatic discharge machining requires electrodes, insulating

fluids, and power supplies. The power supply connects the electrode to the

workpiece. The spark generated by the connection creates a channel. Unlike wire

EDM, sinking EDM does not completely cut the material. This allows our

operators to generate complex shapes. At the same time, it does not create

stress in the material. This makes it an excellent means of producing injection

molds and stamping dies. But comparing to CNC milling and turning, the process

speed of sinker EDM is slower. Besides, surface will be rougher.

Wire EDM

Wire EDM, as its name suggests, uses wire discharge current to

feed conductive metal parts. Both the wire and the workpiece are located below

the dielectric layer. This wire is thin and tight. It acts as a cathode in this

process and usually penetrates the material completely, and the operator can

adjust this to cut only the part, but a complete cut is more common. The result

is a very precise cut.

Advantages of CNC prototype machining

With combination of above equipment, custom machining brings a lot

of benefits to manufacturers. These benefits include:

1.

Save manufacturing costs

By using CNC service, you can take advantage of all the raw

materials involved in the manufacturing process. Due to the precise operation

of CNC machines, waste is greatly reduced. This helps CNC machine operators

minimize any losses they may suffer and increase profitability over time.

2.

Increase production speed

CNC machining is a very efficient machining method. Because of

this, the production process of CNC machine tools reduces the number of steps

required to produce a specific part. As a result, you can produce multiple parts

or projects in less time than other manufacturing processes.

3.

Increasing the safety

The entire CNC prototype machine is automated. Therefore, the

machine operator does not even participate in the production process. This

creates a safe environment because the machine can do all the work without

anyone present. Some production involves potentially hazardous materials such

as metals or steel. CNC machining is so precise that it poses virtually no

safety risk.

4.

Improve production efficiency

CNC machine tools are considered to be the most effective system

for designing parts. This is because most CNC machines are equipped with built-in quality

assurance protection. Therefore, when a problem occurs during production, the machine

detects it and closes it to prevent further problems or fix the problem

internally.

5.

Reduce production costs

A properly functioning CNC machine should work flawlessly for a

long time without the need to repair parts or repair the machine in any other

way. Since there is a good production process from the beginning, and because

there are few defects, there is a few maintenance work, so the production cost

is very low. The budget of any company may be significantly reduced by the

manufacturing sector. But with CNC machines, this process can save a lot of

money.

This design was transformed into a physical prototype, which was

time-saving and attracted many customers because of its aesthetics due to the

use of modern rapid prototyping technology. A lot of software are available for

designing purposes now a days which are easy to use and have better interface

as compared to old software.

Comments

Post a Comment