The Application of Rapid Prototyping manufacturing

What

is rapid prototyping manufacturing?

Rapid

Prototyping (RP) is an advanced manufacturing technology when developed rapidly

in the 1990s and provides service for development of new product in the field

of manufacturing. It plays a proactive role in promoting enterprise's product

innovation, shortening new product development life cycle

and improving product competitiveness. Since PR comes to life, the technology

has been widely applicable for manufacturing industries around the world, and thus

creating an emerging field of technology.

As a

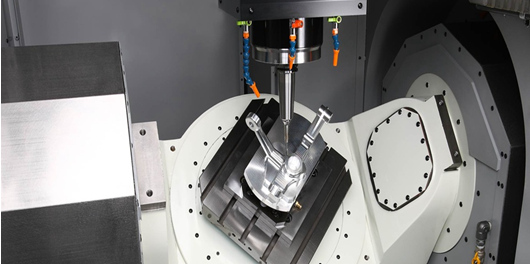

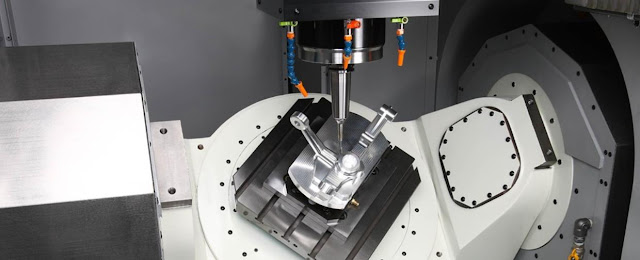

whole technology group, rapid prototyping integrates with a set techniques of

CAD/CAM, laser, CNC, precision servo drive and new materials, directly driven by

the CAD model can quickly create arbitrarily complex shape of three-dimensional

physical entity. Different types of PR system have different molding principle

and system features due to PR are used different materials. However, applicable

principles of most of PR systems are almost the same, manufactured by

layer-making and layer-by-layer stacking.

1) Design

verification and function verification during a new product.

2) Gaining

great advantage over Manufacturability, Assemblity Inspection and Supply

Request and Marketing, the RP method is used to test and design the complex

systems of limited space, such as automobile, satellite, missile, and assembly,

finally drastically reduced design and manufacturing difficulty of system.

3) Instant

and direct production of single part, small batches and special complex parts

4) Rapid tooling manufacturing. It

is commonly used for Low melting point alloy mold, silica gel mold, metal cold

injection mold and ceramic mold etc.

1) Automobiles

and motorcycles: Appearance & interior parts design, modification, assembly

experiment, trial production of engines and cylinder heads.

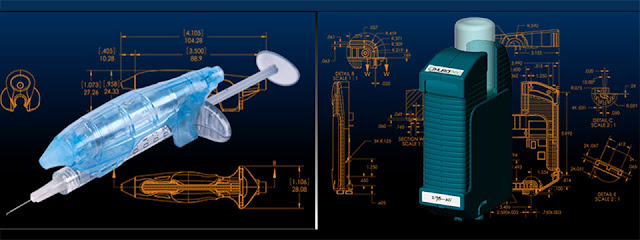

2) Home

appliances: the Appearance and structural design of various home appliances, assembly

experiment and functional verification, marketing, and mold manufacturing.

3) Communication

products: Design of product shape and structure, assembly experiment,

function verification and mold manufacturing.

4) Aerospace

and aviation: Direct production of special

parts, trial manufacturing of impellers, turbines, blades, trial production of

engines, and assembly experiments.

Conclusion

Rapid

Prototyping Manufacturing almost covers every industries, including Medical

treatment, Human engineering and Heritage conservation etc. With technology

improvement, its application will be wider and wider.

Comments

Post a Comment