What Is Rapid Prototyping Manufacturing ?

Rapid Prototyping Manufacturing

Back in the days, coming up with a design from

conceptualization to its output would take long, and was costly compared to

modern times. The onset of rapid prototyping has brought about a couple of

changes in the production process.

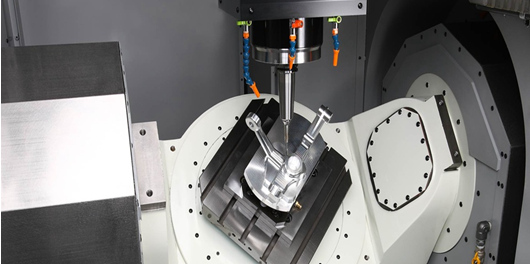

Rapid prototyping involves bringing together

several crafts used to design the physical representation of a particular

object. It is made possible with the use of a 3D computer-aided design data,

popularly referred to as CAD. 3D printing technology is used in the

construction of the pieces used in assembling.

Rapid prototyping manufacturing is the most

preferred procedure by most tech industries because of its ability to bring out

high precision and top quality models. There is a wide range of items that

cater for both medical and industrial applications using traditional 3D

systems. This procedure is also preferred by many because it is solid-free.

A production prototype is an example of a

product. It is discharged to producers and who test its ability to work

successfully before forwarding it for production. Aspects like longevity, work

rate, the cost, and production difficulties can all be ascertained through the

creation of a precise prototype.

Before the rapid prototyping technology was introduced,

this method was very slow and expensive than it is today. Developing products

was not a straightforward affair, and this led to the dissolution of most ideas

even before they were implemented or used for a test run. We have seen

significant progress in rapid prototyping technology over the past few years

which has brought about improvements in the prototyping procedure.

The method used in rapid prototyping can be summarized into the following steps:

The method used in rapid prototyping can be summarized into the following steps:

- Construction

of a computer-aided design (CAD) model

- Conversion of the model into stereo lithography

(STL) format.

- The

rapid prototyping machine is used to process the STL file by producing cut

portions of the model.

- Various

parts of the physical model are then produced.

- Anything

that holds up the structure of the model is removed.

- The outer part of the model is now complete and can be cleaned.

Rapid prototyping types and how

they are used

There are various procedures of rapid

prototyping which can be used depending on the design created or the materials

that are to be used. They include:

3D printing

It was introduced during the early 90's by

students from the University of Massachusetts. 3D printing is now common in

most places, some people even referring rapid prototyping to as 3D printing

despite the different methods used. This type of printing works by setting up

several lines or columns of powdered substance, and the use of a liquid joiner

to come up with a solid shape.

Selective

laser sintering

This procedure was also introduced in the

mid-80's. Also known as SLA printing, it involves the use of printers to come

up with a solid substance. All this is made possible by the use of thin layers

of light-activated resin. For every layer of resin used, ultraviolet rays are

directed towards it to help turn it into a solid state.

There is a file format used by computer-aided

designers (CAD) to come up with three 3D objects. Manufacturers are using the

format, popularly known as STL in coming up with computer-aided designs and

rapid prototyping.

Fused

deposition modeling

Fused deposition modeling was introduced in

the early 90's. It involves the creation of a 3D object with the use of

thermoplastic beads. They start hardening upon ejection, therefore, creating a

solid substance. One key benefit of fused deposition modeling is that several

tubes can be used in the extraction of beads, which makes it possible for the

formation of prototypes with different varieties of colors and distinct

materials.

The significance of rapid prototyping to the manufacturing

sector

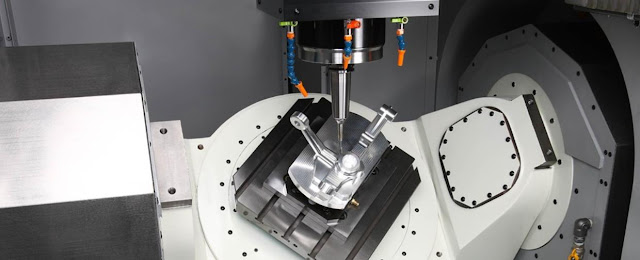

The main benefit of using rapid prototyping in

production is the fact that can produce a definite model of an item, which

gives engineers, designers, and manufacturers the chance to study several

visible features of a particular object before starting in-depth production.

Prototypes can be examined for comfort design, artistic applications, and

output without difficulties.

Stereo lithography printing method is

especially beneficial when it comes to experimenting accuracy of parts. The use

of thin light-activated layers with stereo lithography printers helps in the

production of very accurate designs which can be used to analyze pressure,

steadiness of a load, balance, stress resilience, and simplified performance.

Rapid prototyping has helped reduce the design

process, or the time taken from when one comes up with a product idea to its

manufacture. One can come up with an accurate design in a span of one to two

days without spending so much money. If your model is endorsed, the industrial

production and organization of manufacturing equipment can start, while

finalizing the last bits of your design. This will help reduce the period of

production and save more costs.

Benefits of rapid prototyping manufacturing

Benefits of rapid prototyping manufacturing

Suppliers and customers are some of the people

who get to benefit most from fast prototyping manufacturing. Suppliers get to

use the designs made using the rapid prototyping process to give a more precise

valuation of manufacturing time and expense. Stereo lithography designs can be

used as the main arrangement used to make metallic sculpture. This will help

minimize the time required for factory arrangement and assembling.

Customers get to enjoy the benefits that come

with rapid prototype manufacturing when they get the chance have a hand on the

precise design of the item they want to develop. It gives them the confidence

to kick start the manufacturing process after examining the designs and make

several amendments. Customers also have the chance to save on both the design

and production process.

Conclusion

Rapid prototyping manufacturing has helped

make the production process easy by bringing out clear designs. Producers

should embrace this form of technology because of the benefits that come with

it. If you are looking forward to saving time and money, then rapid prototyping

manufacturing is the way to go.

Comments

Post a Comment