What is CNC Suitable for Processing?

With

the rapid development of computer technology, people's life and the computer is

more and more close. This close connection is gradually reflected in the

manufacturing industry, in which CNC has become an indispensable link. The

rapid development of CNC parts also makes people have more knowledge and

understanding of it, today we will discuss ‘what kind of parts CNC is suitable

for processing?’

Common techniques: turning&milling

First,

let's look at the two most common CNC machining techniques: turning&

milling

1. Turning

CNC

turning usually refers to the lathe tool on the rotating parts cutting process,

it is usually more work with a rotating surface of some parts. CNC turning

parts are widely used in aerospace, communications, computer, electronic and

electrical, automotive, machinery, instrumentation, valves, sheet metal,

lighting, furniture, bathroom and other industries, and are highly praised by

users.

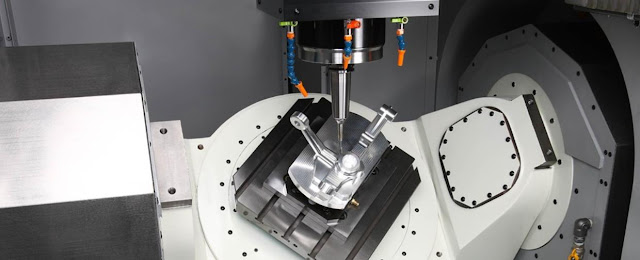

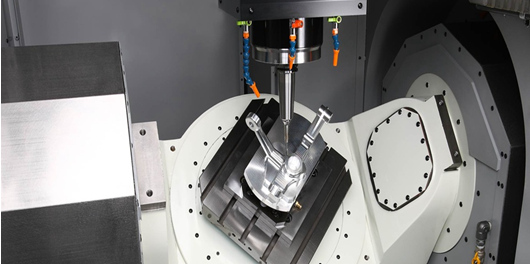

2. Milling

Milling

usually refers to the blank fixed, with high-speed rotation of the milling

cutter in the blank knife, cut out the desired shape and characteristics. The

difference with turning is that in CNC milling parts, the cutter rotates at a

high speed under the drive of the spindle, while the parts being processed is

at a relatively static state. Traditional milling is mainly used for milling

simple contour and groove. CNC milling machine can process complex shapes and

features. Milling and boring machining center can be three axis or five axis

such as multi - axis milling and boring machining.

CNC suitable for processing What?

So

in the modern processing industry in a wide range of times, CNC machine tools

suitable for processing what type of parts? In the processing industry, CNC

machine tools are mainly used for processing metal mold, aluminum alloy and

other CNC parts. Through the operation of the CNC machining program, can

automatically complete inside and outside the cylinder, surface, forming

surface, threads and transverse processes such as machining, and reaming,

drilling, turning, turning center can accomplish more in a clamping of the

machining process, improve the machining accuracy and productivity, especially

suitable for complicated shape revolving parts processing.

1. CNC aluminum parts processing

Generally

speaking, with custom-configured CNC milling machines and CNC turning lathes,

CNC machine tools, it simplifies and streamlines our CNC machining processes. Advanced

CNC prototyping services are promptly in keeping up with clients’ demanding

production schedules while being able to handle the operation of various

machining projects and prototyping projects that require precise tolerances,

special materials, complex parts, and optimal efficiency.

Many

industries precision aluminum can be processed with CNC machine tools, such as

automotive, aerospace, medical, electronic, automation industries, these

industries on the aluminum precision requirements are very high, and these

through numerical control processing CNC aluminum parts are often complex structure,

surface requirements of the smoothness is also very high. But CNC machining can

be through turning or precision five-axis milling to process complex structure,

high precision requirements of aluminum, CNC machine tool automatic tool change

and five-axis processing technology can reduce the number of parts in the

process of clamping, greatly improve the processing accuracy.

2. CNC low volume production

Low

volume production refers to the industrial production, there are a lot of

products due to the technical requirements, the market demand for a small

number or high price and other reasons can’t achieve large batch production, so

choose through mechanical processing, manual production and other methods to

achieve the production of finished products or accessories, which has the

advantages of flexible production, fast delivery, low comprehensive cost and

high manufacturing accuracy.

The

application fields of low volume processing include trial production in the

early stage of product development, special equipment in medical and other

industries, non-standard parts of machinery and many CNC parts from other fields.

And with the rise of personalized customization, the demand for low volume

processing is also increasing.

Low

volume production versus mass production, the technical requirements higher,

because low volume production of parts for the most part are sample, they have

not put in the market, is just an idea, to get it from idea to product, no

experience may refer to low volume production, can only through the

communication with customers \ technical engineers and process data simulation

optimization to reduce the error rate of the processing of products.

3. CNC

transparent parts processing

The most commonly used

materials for CNC transparent parts processing are PC and PMMA (transparent

acrylic), and for the parts with high requirements for transparency and

clarity, we usually choose PMMA as the processing material. At Wayken, we are

very good at process CNC transparent parts. We can combine 5-axis precision

milling with diamond machining technology that gives us the ability to machine

more complex shapes and optical details, utilizing a single set-up, instead of performing

required individual fixturing and repeat positioning for each operation on different

machines.

4. CNC plastic

parts processing

CNC

rapid prototyping parts can be used to create plastic parts, which allows your

design team to closely simulate the final product appearance and function, and

also reflecting the validity of physical dimension and the ease or complexity

assembly work, and yet give the space to modify and optimize design.

With custom-configured CNC milling machines

and CNC turning lathes, CNC machine tools, it simplifies and streamlines our

CNC machining processes. Advanced CNC prototyping services are promptly in

keeping up with clients’ demanding production schedules while being able to

handle the operation of various machining projects and prototyping projects

that require precise tolerances, special materials, complex parts, and optimal

efficiency. Through our CNC machining, you can get perfect prototype

production.

5. Concluding

Remarks

Compared

with ordinary lathes, CNC machining parts is flexible, versatile, high degree

of automation, can adapt to the product varieties and specifications of

frequent changes, especially suitable for the processing of complex shape of

shaft and disk parts, in the development of new products and varieties, small

batch, automation production is widely used. Hence the designing phase is one

of the most important and critical phase of product development as whole

product development process is dependent upon the design. The design must be

optimized and simplified in order to reduce the cost and time of manufacturing.

But the design must allow tolerances in the developed product in order to

increase its fatigue life and prevent it from failure.

Comments

Post a Comment