Industrial design Prototyping

Why is Industrial design important?

1. We live in an

era of consumption where supply is so vast and differentiated that you can

easily find two identical products if you judge by their specifications. That

is where Industrial Design comes on stage. When technical parameters are really close, people

start choosing the product that suits their tastes better, feels better, has

better proportions and so on. That is even more viable when we talk about

gadgets and appliances. Well, for some

people, design is even more important than technical parameters. That is why

industrial design plays a large role in product success or, unfortunately,

failure.

Prototyping for industrial design

Development of digital

technologies in the recent decade has considerably lowered the popularity of

prototyping for industrial design. And really, why bother, when you can create

the whole part or even the assembly on your PC without the need to cooperate

and order a physical product or make it yourself. Designing has seemingly

become much easier. However, that is not completely true. Sure, 3D-modelling is

fast, doesn’t require any materials and you can even analyze and correct the

mistakes you’ve made without any considerable loss. But digital products do not

give us the whole picture. For example, you can’t correctly judge the scale of

your product and its elements. If that is not done, do not be surprised when

your product does not fit into your hand (If it is handheld, of course) or if

some part of it sticks out by being too big or too small. In some cases,

problems may be so dire that the product, having made the transition from the

digital world into our own, may not work altogether. Such things may happen

when the product is made from sheet metal. Depending on the sheet width, it may

buckle under its own weight or be so heavy, that you’ll need to make it for two

clients to carry and not just one. That is why making prototypes is so important

and most serious companies male prototypes or mock-ups of their products to optimize

them for consumers.

If we want to

understand the advantages of prototypes, we should refer to the most successful

companies and look at the ways they achieve advantages through the usage of

prototypes. Let’s start with Apple. The IPhone and IPad designs they initially

make for a new model are numerous and very different in size and style. What is

different about them compared to other smartphone manufacturers is that they

make mockup models of all the phone designs and tinker with them. They change

proportions to make the phone sit better in your hand, they move the buttons

around and what is the result? A very ergonomic convenient and stylish design.

As a result, most other smartphones have a similar case but the original idea

still belongs to Apple. It is known that Google started using prototypes for

their products too, following the example of Apple. In some cases, you just

can’t avoid making a prototype, for example, in turbine industry, you have to

make different calculations of the way gas will move through the turbine blades.

That is most often done using Finite Element Analysis and 3D-modelling using

meshes. However, the models that are used there cannot take all the factors

into account. That is why after designing a turbine blade, a physical prototype

of it has to be tested and its performance verified. Only through the use of

prototypes can we enjoy safe and stable flights and energy production.

New methods of Making Prototypes

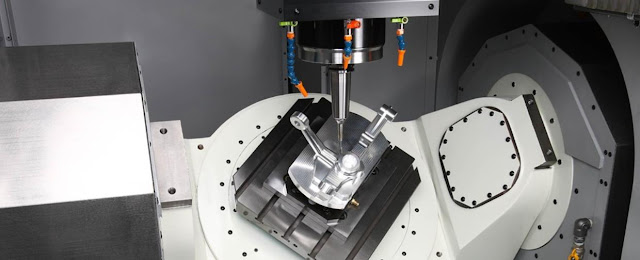

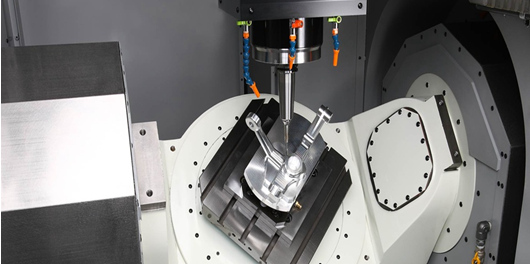

Well, conventional methods of making prototypes

have existed since the birth of prototypes themselves. And what could be more

logical? You have designed a product and you make a couple of fully functional

prototypes and you test both the design and the manufacturing technology. This

method is the most thorough one. You can test the technology, the design, and

the functionality. However, modern industry nomenclature is changing at a rapid

rate. Products can come and go to be changed by new ones in less than a year.

The company that has the smallest product lead time wins the market. That is

why making a fully functional prototype is often not viable, especially

considering newer product versions when the general functionality has already

been established and is just upgraded in some of its aspects. Thus, mockup

models were made. Their advantage is such that you only make the outer carcass

and test it. Convenient, isn’t it? You only order some company to cast you a

plastic model or for someone to mill you a metal one on a CNC center. Well,

prototyping has come one more step ahead. So-called Rapid

Prototyping managed to decrease

the prototype manufacturing time even further. The main technology here is

Additive Manufacturing, a very popular innovative method of layer-by-layer

sintering of different materials. Its main advantage is flexibility. You

basically need no additional equipment or tools apart from a 3D printer and

stock material. If you make a plastic prototype, you don’t even need to mind

technology that much. The software of commercial printers is usually so

advanced that it forms sintering trajectories all by itself, thereby no technological

preparations are needed and they take most of the time

when making a prototype. It should also be noted that the quality of Additively

manufactured parts has risen drastically. Some of the plastic parts, made by

SLA-printers for example, have the surface finish that of a plastic mold. Some

printers can even make colored prototypes. If we talk about metal printing,

progress here is also notable, as SLM-printers can now produce parts with

tolerances up to 0.016 mm which is fairly good and enough for a lot of parts

when we consider precision.

Conclusion

To summarize the

whole article, 3D-modelling is very important in industrial design and it has a

lot of benefits when we consider flexibility, analysis and visualization,

however, if you are aiming to make a truly outstanding product, 3D-modelling is

not enough. In order to judge the scale, rigidity, and size of your product

ideally, you have to make a prototype.

Recent technological developments come to our aid here, allowing us the

use of Additive Manufacturing, a layer-by-layer sintering technology. It

provides designers a rapid and profitable way to make prototypes and further

reduce the lead time of the product.

Comments

Post a Comment