Modern mold technology

Modern mold making technologies and

trends

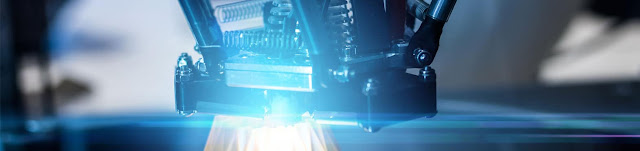

The principle of electrical discharge machining

involves local evaporation of material under high voltage. The main advantage

here is the ability to machine any type of electricity-conducting material with

no regard to its strength or machin ability. The precision and surface finish of

that method is good enough for most commercial molds. Another way to increase

the speed of creating molds is to use SLS-printing. SLS-printing is an

innovative way of sintering metal powder layer-by layer to produce a part

without any need of tools and fixtures. So, creating a 3D-printed work piece

drastically decreases the amount of machining that is required to produce a

mold. It also decreases the amount of material waste from around 50-60% to 20%

which is very high. In case of producing parts from a low melting temperature

plastics, where metal molds are not needed, it is possible to 3D-print the part

mock up using SLA-printing and then create a mold based on that part (for

example creating soft rubber molds).

As

of now, mold technology is divided into a number of different molding types:

·

Injection molding. This one is the

classic process where molten plastic is injected into the mold under pressure

and is then crystallized;

· Intrusion molding. The process here

is different from the first one in the way of feeding plastic into the system.

The Pressure is lower but the material is supplied by a special gear mechanism

which works during the whole process and adds more material to compensate for

the shrinkage during crystallization. That is really important when creating

parts with wide walls.

·

Gas-Injection molding. This

modification of injection molding fills the mold up to 75-80% at first and then

blows some inert gas into the mold. The gas is under pressure so that the

plastic fills all the nooks and niches of the mold better. After a few minutes,

the gas is pumped out and the mold is filled with plastic completely. This type

of Injection molding is great for parts that have long and thin walls.

·

Combination Molding. This process is

almost completely like the classic injection with only one difference. Two

types of material are used. For the outer surface, one color or type of plastic

is used and the other one is for the inner surface. It brings many

opportunities to manufacture parts with different color or properties depending

on their surface.

So,

as you can see, the method of injection molding is well researched and

developed and depending on the type of part you make, one or the other method

will bring you better quality and lower cost of the product to be manufactured.

Modern molding technologies

So,

the mold has been created and the actual process of producing parts may be

considered. In most cases, it consists of a number of stages:

·

Preparation. This stage consists of

measuring the composition of plastic to be molded, colorant is added at that

stage and the whole substance is dried to prevent pores.

·

Machine tool setup. The molding

machine parameters such as temperature, pressure, molding time are chosen by

the operator and the mold is fixed into the machine.

·

Loading. Here, the required amount of

injection material (a mixture of plastic, special additives and colorants) is

loaded into the machine bunker.

·

Injection. This process consists of

heating the plastic until it melts and injecting it under pressure into the

mold.

·

Crystallization. This is the last

stage and the longest since the part must cool down to be removed.

As

a result of the process and removal of some additional structures required for

molding, a very precise part with fine surface finish that requires no or some

finishing postprocessing.

Conclusions

Manufacturing of plastic parts is a rapidly developing

industry. That is logical since more than 60% of current products consist of

plastic parts and Injection molding is the mechanism that allows a reliable and

repeatable creation of parts of the highest quality. Mold technology also has some

disadvantages, the main of them being the complexity and the large costs of

molds. This somewhat determines the area of its use: manufacturing identical

parts in large volumes. However, extensive work and research is being conducted

to negate this disadvantage. New technologies are being adopted to produce

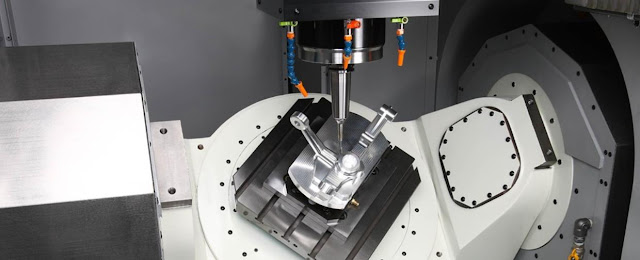

molds, such as 3D-printing and EDM machining. New designing methods and

templates for making and modeling molds are being developed (most CAD|CAM|CAE

systems of high level have a special mode for designing and testing molds). All

of the work mentioned above moves the use of injection molding from a

technology of mass production into the industry of low quantity and custom

production.

Comments

Post a Comment