CNC VS SLA and SLS printing

CNC machining and 3D-printing (SLA or SLS) are the main methods of

producing Prototypes and commercial products when the weight

of the initial stock and the final product are different. The part creation

principle, however, completely opposite. It is important to understand the

differences between them in order to be able to choose the required method to

produce your own sla prototype correctly.

CNC Machining

and its benefits

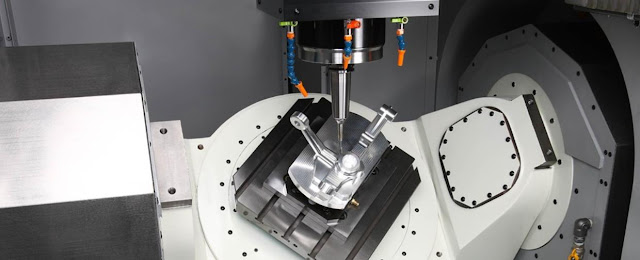

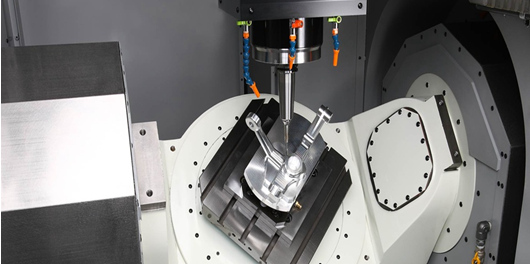

CNC machining

is the oldest of the three methods and the only subtractive one. It means that

the mass of the stock gets lower as its condition gets closer to the final

part. The material is removed from the stock material by using different

cutting tools that move according to a CNC program. The most widespread machining centers feature

turning or milling as the main machining methods and if the precision of the

part is high, grinding and polishing will get you the desired results in

tolerance and surface finish.

CNC machining is the most precise method when

compared to the other three because cutting offers increased rigidity, lack of

thermal distortion and the initial material of the stock usually has a higher

quality when compared to the Additive Manufacturing. Machining has its

disadvantages too. Firstly, it is the longest method when comparing lead time

because of the need to write a CNC program, to install fixtures and to set up

the tools, however, once you have done all of that, CNC machining as remarkable

repeatability and the process itself is usually faster than 3D-printing.

It also requires the highest qualification of the worker as he has to understand the technology to choose the cutting parameters, tool trajectory and the coolant. CNC machining has some restrictions compared to the Additive Manufacturing, especially in terms of inner surfaces because the cutting tool is often too big or can’t get into a complex bent inner hole.

It also requires the highest qualification of the worker as he has to understand the technology to choose the cutting parameters, tool trajectory and the coolant. CNC machining has some restrictions compared to the Additive Manufacturing, especially in terms of inner surfaces because the cutting tool is often too big or can’t get into a complex bent inner hole.

To summarize, CNC machining

is more viable for producing a moderate amount of identical parts than

prototyping, however, in some cases, when precision is concerned, you just

can’t do without it.

SLA printing and

its benefits

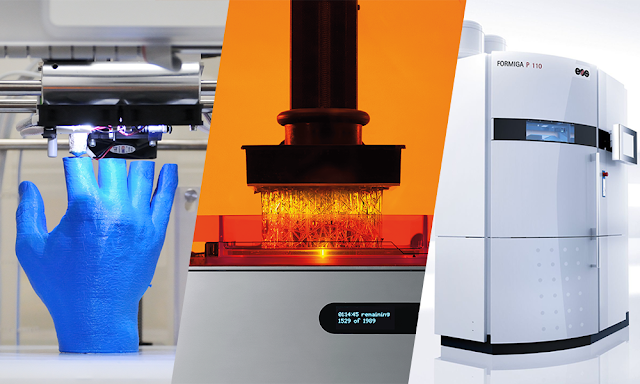

Now, this method is

different from the first one in every way. The weight of the initial stock is

zero, but as the part gets closer to its finished stage, its mass grows. That

is achieved by sintering the material layer-by-layer. In case of SLA printing,

the material can only be plastic (which is its main restriction and

disadvantage, by the way) and it is contained within a reservoir in a liquid

state.

Above the surface of the pool of plastic is a laser or a UV beam. The radiation of the ray hardens the surface of the pool and is then submerged. Then the process is repeated until the whole part is obtained. It is important to note that the surface finish of the part is not worse than if you manufacture it using machining. The tolerances are somewhat worse though (mainly due to a staircase effect, i.e. every layer has its own width, it is not zero, that is why slanting surfaces are comprised of those steps and are rougher).

Lead time in SLA printing is the shortest of the three because you do not need any fixtures or tools and you don’t need to write the CNC program. The printer does it for you. And the manufacturing opportunities are limitless because you can make almost any type of complex structure that is impossible to be worked by machining. That is why SLA-printing is great for making smooth plastic prototypes but it can’t do much more than that and CNC machining can still achieve a better surface and precision if you use grinding in the end.

Above the surface of the pool of plastic is a laser or a UV beam. The radiation of the ray hardens the surface of the pool and is then submerged. Then the process is repeated until the whole part is obtained. It is important to note that the surface finish of the part is not worse than if you manufacture it using machining. The tolerances are somewhat worse though (mainly due to a staircase effect, i.e. every layer has its own width, it is not zero, that is why slanting surfaces are comprised of those steps and are rougher).

Lead time in SLA printing is the shortest of the three because you do not need any fixtures or tools and you don’t need to write the CNC program. The printer does it for you. And the manufacturing opportunities are limitless because you can make almost any type of complex structure that is impossible to be worked by machining. That is why SLA-printing is great for making smooth plastic prototypes but it can’t do much more than that and CNC machining can still achieve a better surface and precision if you use grinding in the end.

SLS printing and

its benefits

This type of prototype

manufacturing is closer to SLA printing as it is an additive method too. Its

main difference is the material. SLS printing deals with metal. The main

principle here is spreading the metal powder in a thin layer and sintering it

with a laser. Due to the fact that powder grain is very small, you get a high

quality sintered part and most of the laser trajectories are software produced.

However, metal sintering is much more complex than plastic melting and 3D-printing software is not yet at the level required to process all the issues that occur when sintering metal powder. That is why lead time in SLS-printing is higher than in SLA and also, due to the innovativeness of the process and the lack of full-fledged research, the number of defects is considerable.

The final surface finish of the parts is also lower, up to 2-4 times that of CNC machined parts. Despite that, SLS printing is still much easier and faster when we talk about making prototypes. You still don’t require any tools or fixtures and the amount of waste is much lower (up to 80%) compared to CNC machining.

However, metal sintering is much more complex than plastic melting and 3D-printing software is not yet at the level required to process all the issues that occur when sintering metal powder. That is why lead time in SLS-printing is higher than in SLA and also, due to the innovativeness of the process and the lack of full-fledged research, the number of defects is considerable.

The final surface finish of the parts is also lower, up to 2-4 times that of CNC machined parts. Despite that, SLS printing is still much easier and faster when we talk about making prototypes. You still don’t require any tools or fixtures and the amount of waste is much lower (up to 80%) compared to CNC machining.

Another advantage of 3D-priting is the ability to create complex shapes,

lattice and cellular structures. You can redesign the product itself to make it

lighter, hollow with inner supports and still as strong as if it was solid.

Another advantage of 3D-printing with metal compared to CNC machining is the

ability to produce composite alloys in situ or so-called metamaterials. The

first ones are obtained by sintering together different powders and the second

ones can be made by sintering different layers. Both of material types enable

the creation of parts, whose material properties differ with dimensions.

SLS-printing is a process that may be able to define the product instead of

being defined by it and it may be its main advantage.

Conclusion

Having looked at the methods,

it is now possible to assume their respective areas of use. CNC machining is

viable when a number of parts is needed or when very precise tolerances or fine

surface finish are necessary. Now, SLA-printing is ideal for making plastic

prototypes of great quality and SLS printing is great for creating metal

prototypes with innovative design.

Comments

Post a Comment