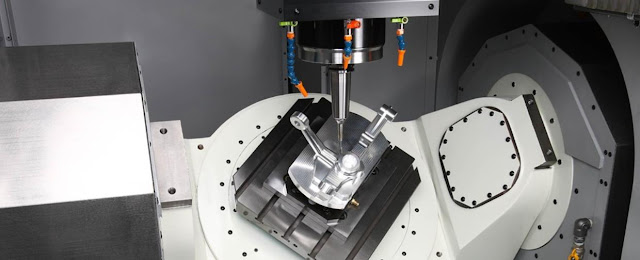

Prototype Machining Services

Prototype

machining services are industrial

services offered to clients and these machinations are normally drilling,

turning, welding, and threading to name a few.

The sizes vary and so, too, do the diameters. Clients are able to order custom-made parts

which are small in numbers. Therefore,

these are not enough for low-volume manufacturing; neither are they enough for

manufacturing on a regular basis.

Prototype machining services are for innovative clients who have an

affinity for designing and need custom-made parts to achieve different effects

or styles.

The main purpose of these custom-made

parts is to experiment with new concepts to achieve the preferred product or

perhaps to upgrade a now obsolete prototype.

It is very simple to make minor modifications to the current part; and

this may be done by adding to the product lifespan, lengthening or shortening a

part, varying the thread pitch of a bolt and changing the product dimensions,

for instance. you can click here.

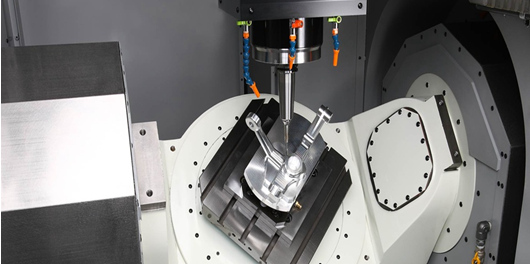

Prototype machining services of the

custom-made part are made after reliable evaluations are completed. Therefore, rapid prototyping is done

expeditiously at each stage throughout the machining process. As each client’s conditions need to be met

and are not similar to each other’s specifications, time-frames for each job

differs considerably. There are also

other aspects that are needed to be taken into consideration; and these are the

existing orders to be fulfilled, obtaining external needs and the accessibility

of the material needed in order to start prototype machining processes.

Top 5 Advantages of Rapid Prototyping

Top 5 Advantages of Rapid Prototyping

a.

Understanding and Achieving the Concepts of Design

Prototype machining services enable engineers to achieve the models that they had only envisioned. They can now experience the tangible model instead of trying to get a grasp of the computer-aided design (CAD) design. Engineers are then able to improve their prototype, so the end product would be exactly what they required. In this way, the client would have the tangible product and there would be no need to use the CAD design in this instance either.

Prototype machining services enable engineers to achieve the models that they had only envisioned. They can now experience the tangible model instead of trying to get a grasp of the computer-aided design (CAD) design. Engineers are then able to improve their prototype, so the end product would be exactly what they required. In this way, the client would have the tangible product and there would be no need to use the CAD design in this instance either.

b.

Immediate Modifications

When the

engineer has the prototype, the necessary modifications can be made promptly

when consumers test products. Before

confirming the design’s modifications, there is a lot more prototype machining

to be done as this assures both the engineer and customer as to the quality of

the product. As a result, the developing

engineers will be able to better assess the current need of consumers, so they

will then be able to modify the product and be more competitive in the

marketplace. Therefore, the product will

be able to gain a better reception and profit margins will automatically be

higher.

c.

Saving Time and Money

Time and

money are being saved during additiPrototype machining servicesve manufacturing; therefore, there is no

need to improve on molds, designs and special parts. CAD and 3D printing machinery may be

necessary in order to create various parts.

In this way, there is less material and products to be discarded because

rapid prototyping designs parts that are necessary for the construction of

these items/products.

Ford has

openly declared that it has printed more than 500,000 parts and that millions

of dollars have been saved with the 3D printing method in addition to thousands

of hours of work.

d. Model

Customization

The

improvement of customized products according to client’s designs is the

greatest advantage of rapid prototyping.

There is no need for specialized tools or methods for the implementation

of the product model alterations. The

procedure remains as is even when there are minor adjustments to the CAD

design. This is definitely a plus for

the industrialists as the customers are able to develop a connection with their

purchased merchandise.

e.

Minimization of Defective Models/Items

Defects

and flaws in the model designs are identifiable through the additive

manufacturing process. Therefore, the

physical examination of the product is effortlessly completed as the materials

which are used for the rapid prototyping process is very similar in the makeup

of the tangible product. This minimizes the defects and flaws that users may

encounter as these are recognized in the early stages so that glitches may not

be encountered at a later point in time.

Conclusion

Rapid prototyping is a lucrative option,

and this method of product modeling, development and improvement is highly

applauded in today’s world which integrates business and engineering. In order to become more competitive in the

industry, this implementation should be of great interest to the creative mind

who wishes an alternative to the costly methods which are quickly becoming

obsolete.

Conclusion

Comments

Post a Comment