The Concepton And Benefits of CNC Prototyping Service

CNC Prototyping Service

The manufacturing sector broadly depends on

CNC (Computer numerical control) machining. CNC is the process of cutting

materials with the help of a computer numerical control machine. The CNC

machining procedure deciphers your 3D computer-aided design model and spells

out data to its devices. The critical gain of the whole method is that CNC will

come up with parts that can substitute the extra mass-produced models with real

production quality materials. This style gives you the chance to create your

parts from the highlighted stuff that you want to use for production purposes.

CNC machining is the perfect choice for fast prototyping of top-level metallic

and plastic pieces that do need high levels of spatial precision, vital surface

completion and clear-cut material characteristics.

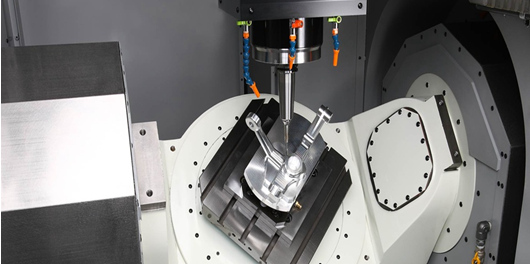

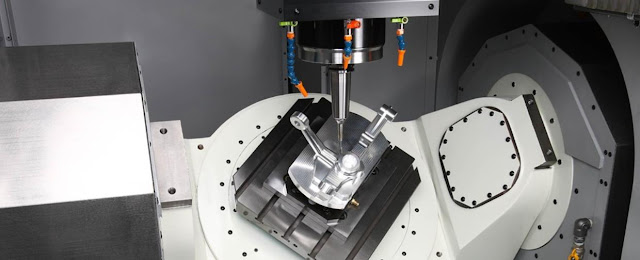

What it means by CNC machining

CNC machining is a deductive production method

where necessary resources are removed using a couple of tools that bring out

accurate cuttings to make complete products or pieces used in bringing up the

finished item. A leading software is used to guide the used machine depending

on the blueprint of your dimensional design. A group of qualified engineers and

machine operators are responsible for programming the apparatus to make good

use of the cutting time, outward finish and the last endurance to come up with

something that suits your preference. The CNC machining process is not only

used in the production of parts and models but also to manufacture mold items,

which can be used for our plastic injection molding or pressure casting

services.

What is a CNC machine?

This is a type of machine that makes use of

Computer Numerical Control over machine apparatus like drills, grinders or

millers. Computer Numerical Control is contrasting to the traditional computers

when it comes to the software used in operating the machine. It is ordinarily

custom-built and set up with G-Code, which a specific CNC machine operating

system that provides accurate control of features like arrangement, speed,

site, and supply rate

One computer expert at the computer section

can prompt machine work which is similar to a couple of operators on various

production machines. The programmed, computerized machining method can

accomplish a couple of things workforce and traditional tools cannot do with

the much-needed efficiency.

CNC

machining is of great importance when it comes to production because it

gives room for the production of metal and plastic pieces in large quantities

and the required designs. Several CNC machines have some cutting tools which

can be twisted to several angles that can be used in cutting hard materials.

Traditional machines have a unique cutting formula

across the various types of the axis which can work on their own at about the

same time. Ultra-modern machines may contain up to five cutting types of

equipment that operate concurrently and are capable of revolving to spin the

part. One instance is when the Z cutting tools ascend and descend

simultaneously.

These machines can mechanize works that need a

couple of cuts. A shaft or axis turns the cutting tools which usually looks

like the bit of a drill. We all know that bits are used to cut the tip of a

particular object. The cutting materials of this machine will reduce the

required part of the material.

The programming in these machines combines all

the demanding, fast speed accelerations required for the production of the

item, and it also gives room for particularized adjustments. This procedure is

becoming a fast-rising favorite way of manufacturing metallic objects and also

plastic ones. It is because it gives the producer an opportunity to come up

with intricate structures that would be almost not possible to produce using

human resources. Many manufacturers, production industries being the common

ones are weighing on the CNC machining benefits for their production answers

when it comes to metallic and plastic items or any form of machining procedure

they may require.

Benefits of CNC machining

CNC

machining is efficient compared to the use of other conventional methods. This

procedure comes with a couple of advantages which include:

●

Minimal labor required- Less human labor is

needed for this procedure. One experienced operator can work on a couple of

machines. You are also in a chance to save on workforce costs using this

production process.

● High levels of accuracy- The use of advanced software and modern machines help increase the

accuracy levels in this procedure. All these have helped reduce the chances of

human error.

● Reliable strength- The machine used in this procedure can run for long hours. This means

there will be non-stop production except for when it will need repairs or

maintenance.

● Increased production- Once you enter the design you need to the CNC machine, it will

routinely produce high quantities of your design within a short period.

● It is cost-effective- The combination of fast speeds, high accuracy levels, precision and

the use of less labor time helps in saving a lot of money. This gives one a

chance to create a combative gain and more business investment.

● Little maintenance- CNC machining procedure requires minimal maintenance because the

software used can update itself inevitably when needed. The machines used

require less service which also helps save costs.

● Safety- One gets to enjoy a safe working environment with the CNC machining

process. Those operating the machines are a distance away from the sharp,

cutting objects. They can only come to contact with other tools that pose less

danger to them.

● Design maintenance- When you enter a particular design into the machining software, it is

saved and can also be used at a future date. You can run it to create a product

of similar model at a later time. This saves you the hassle of producing the

same design over and over again.

Comments

Post a Comment