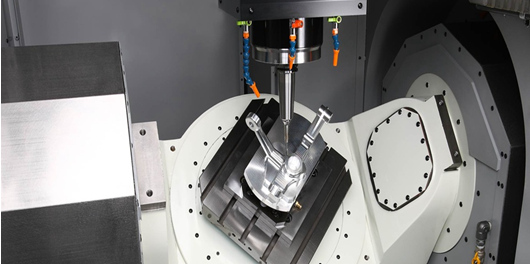

CNC Maching Manufacturing

Rapid prototyping if often discussed

alongside 3D printing, making the two terms seemingly synonymous. That isn’t

the case, though, as 3D printing is only one way of achieving the goal. There

are a group of technologies all capable of rapid prototyping, and this includes

a process called Computer Numerical Control, or CNC.

CNC is the automation of machine tools

whereby computers are programmed with a set of sequences that manufacture the

needed parts. These sequences allow the machine to run on its own, in contrast

to machines that used to be manually controlled by hand wheels or levers. In

addition to it’s automation, the same machine—or cell—can have several

different tools attached to it, all of them programmed to do a particular job,

or the tools can be separated out amongst several different cells, all designed

with for a different purpose. Both of these types of designs are highly

automated and drastically reduce the steps needed to create any part that

closely matches the specifications of the original design.

When a part is needed to be manufactured,

the part’s dimensions are defined by using computer-aided design, or CAD. This

software can be used to create a 2D or 3D blueprint of a part. The software can

then be used to analyse the part and even optimise it’s design. Once the design

is complete, the machine can take this file and transform it into the specific

commands necessary for each tool to create the part. These commands are then

loaded into the CNC and the part can be created.

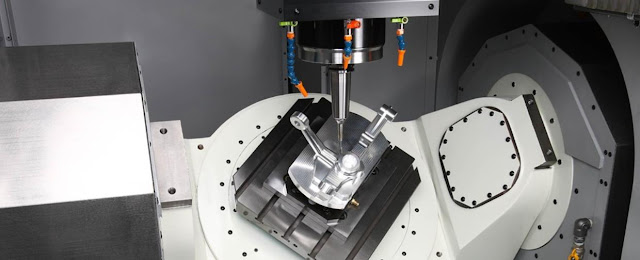

Additive manufacturing, or 3D printing, is

the process of adding on layers upon layers of material. This is the opposite

of CNC machining, where the machine strips away layers of material by cutting.

With CNC, you start with a cube of material and the machine will remove

sections of it, cutting away all the excess material to craft the needed part.

Just like 3D printing, CNC machining can work on the X, Y, and Z axis. This

allows materials to be machined in three directions.

Despite the fact that they’re exact

opposites, you will often find them frequently used side by side. Several

machines do combine the 3D printer with a CNC mill—the machine will 3D print

the part before using the CNC to trim away excess material and refine the part.

Just like 3D printing, CNC can be used for a

lot of different manufacturing processes, such as prototype concept models,

visual presentation prototypes, design verification, and low-volume

manufacturing. Often, CNC is low-cost, which enables businesses to change their

designs or make sure the product works as it is supposed to. CNC prototyping

can be achieved with a range of materials as well, such as plastic, metals, and

other composite materials.

This allows for all different sectors to be

able to effectively use CNC machining. Acrylic and polycarbonate materials can

be used for clear components, such as automotive lights, all the way to the

other end of the spectrum, where squares of wood can be whittled away to create

beautiful sculptures or pieces of art.

The first Numerical Control machines were

built in the 1940’s and 1950’s. They were based on existing tools, modified

with motors that moved the controls. The machine knew where to cut based on a

roll of punched tape. Those early machines were rapidly augmented with analogue

and digital computers that eventually morphed into the modern CNC machines that

we know today. Those early machines revolutionised the machining process. No

doubt the industry would be very different today if those machines were never

built.

Today, there are several different types of CNC machines. Mills translate programs consisting of specific numbers and letters to move the spindle to various locations and depths. Today, these can have 3 to 6 axes. Lathes cut while the piece is rotated, making fast and precise cuts using tools and drills. These types of machines are effective for complicated programs designed to make parts that would be impossible to make on manual machines.

Today, there are several different types of CNC machines. Mills translate programs consisting of specific numbers and letters to move the spindle to various locations and depths. Today, these can have 3 to 6 axes. Lathes cut while the piece is rotated, making fast and precise cuts using tools and drills. These types of machines are effective for complicated programs designed to make parts that would be impossible to make on manual machines.

Plasma cutters use a plasma torch—an

artificially generated state of matter, where a neutral gas is subjected to a

strong electromagnetic field to the point the substance becomes electrically

conductive—which is commonly used to cut through steel and other metals, but it

can be used on a wide variety of materials. The plasma is hot enough to melt

the material being cut and moves fast enough that the molten metal is blown

away from the cut.

Electric Discharge Machining, also known as

spark machining or EDM, is a process where a shape is outlined on the material

with electrical discharges, or sparks. Then, material is removed from the

workpiece by rapid, reoccurring discharges between two electrodes.

Lastly, there is Water Jet Cutter, also

known as waterjet. This is a tool capable of slicing into metal and other

materials with a jet of water. It is often used during fabrication of parts for

machinery and other devices, or when the material is sensitive to high

temperatures generated by other methods. It is used in a diverse number of

sectors, including mining and aerospace.

With so many different types of machines and

cutting methods, CNC machining is a versatile and effective way of achieving

rapid prototyping. While it may produce more waste product than 3D printing, because

the material is cut away from a block instead of being printed exactly as

needed, it is still more efficient than mass producing products where huge

amounts of waste are created. CNC being used alongside 3D printing allows

prototypes to not only perform their required tasks, but look great too, as 3D

printing often doesn’t look as smooth and sleek as CNC machining.

Comments

Post a Comment