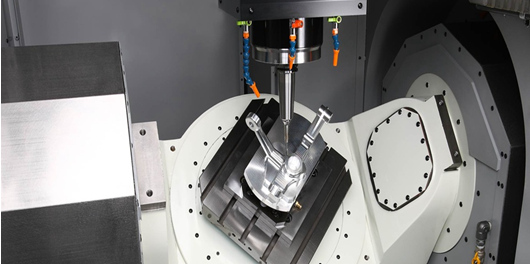

The Concept of Aluminum CNC Machining

Aluminum CNC Machining

There are a couple of methods used in aluminum

removal manufacturing to bring out precision in the final products. The choice

of the components of the production process primarily relies on the final use

and stipulations of the item being produced. It may turn out to be an

acceptable method or a complicated procedure that gives more accurate

requirements, the formation of prototypes or the manufacturing of a

considerable batch of parts. CNC (Computer Numerically Controlled), click here machining is

a skillful procedure of production of an aluminum removal that can be in charge

of a wide variety of manufacturing.

Aluminum is typified by its ability to be

machined and give room for the material with a satisfying finish at a lower

price. The materializing machining strength is to a large extent lesser

compared to that of brass or steel which are a good example. The automated load

of the equipment, the object being worked on and apparatus is therefore

remarkably lower; the energy consumed in every volume per unit of the work piece

is also comparably lower. One more benefit is the approximately low, clear-cut

heaviness of aluminum; it also relatively minimizes deviating forces or

inertial forces, specifically in rotating pieces of work.

What is CNC machining?

It is a process used in the industrial field

which draws in the application of computers to take charge of mechanical

equipment. Tools which are capable of being regulated in such a way consist of

lathes, grinders, routers, and mills. CNC in CNC Machining are abbreviations for Computer

Numerical Control. On the ground, it may look like just a regular computer

controlling the machines, but the computer's unique software and control

instrument panel are the things that get the system ready for use in CNC

machining.

In this type of machining, the cutting

equipment operates with the help of numerical control. A computer set up is

custom-made for an item, and the machines are computed with CNC machining

terminologies referred to as the G-code which takes explicitly charge of most

facial characteristics like coordination, feed rate, speeds, and location. The

computer can control the exact speeds and placements when it comes to CNC machining.

This type of machining is used in the manufacture of both metallic and plastic

pieces.

A computer-aided design sketch is produced in

either two-dimensional or three-dimensional versions, after which one comes up

with a code that should be interpreted by the CNC machine. The command is keyed

in, and it's now time for an engineer to run a test of the command to ensure

there are no complications. This preliminary run can also be referred to as

cutting air, and it is an essential milestone because any form of error with

velocity and tool positioning could lead to a scratched part or a broken

machine.

There are a couple of benefits that come with

the use of the CNC machining process. It is more accurate than the traditional

machining procedures and can be redone in entirely the same way repeatedly. The

accuracy that comes with CNC Machining means this procedure can bring out

complex models that would be somehow difficult to get when using manual

machining methods. This type of machining is used in the creation of many

complex 3D models. These characteristics are the reason why CNC Machining is

used in fields that require a top level accuracy or many repeated tasks.

Aluminum removal production

through CNC milling

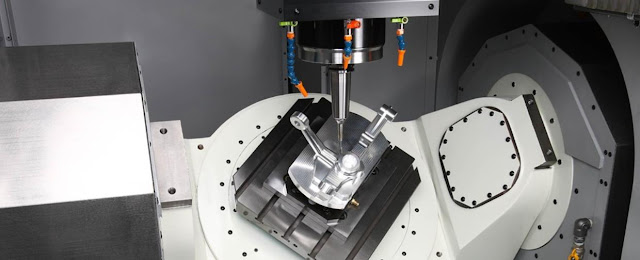

The main reason for CNC machining is to methodically

and precisely come up with indistinguishable aluminum removal elements in an

uninterrupted and regular manner. The following stages are involved in this

process:

● The elements have to go through different intricate machining processes

with no need of human management. This programming procedure will help prevent

resilient disparities in the manufactured items.

● The accuracy that comes with CNC machining brings about total machining

answers with the use of long-bed lathes or short-bed. It also provides

fluctuating and top speed axis horizontal or upright machining and pumping

centers, as well as a mechanic and digital administration equipment. This gives

manufacturers the chance to provide for the manufacture of high accuracy

elements of a wide range of dimensions and configurations.

● Formulated features give room for four axis revolving effectiveness so

that the removal material can be fabricated on every part of its surface with

minimal configurations, counting up to the traditional milling, punching,

bending, welding, cutting and drilling.

Benefits of CNC machining inaluminum extrusion

CNC machining comes with a couple of

advantages besides the production of quality aluminum removal products.

● The automated production process gives room for several trivial

machining equipment, which helps reduce the cost of production because it

requires minimum labor and the eradication of scrap due to human inaccuracies.

● CNC machining is more dynamic as most of the work is integrated into

one location, which helps reduce time frames and make movements more

comfortable, as only one dealer is needed.

● There is increased output with computerization since it is more likely

to have the manufacturing line work without interference for extended periods.

● The levels of safety are high because only qualified engineers can take

charge of all procedures from the command center, reducing the chances of human

interference. The operation can be halted and restored as required to

administer any much-needed remedial actions.

CNC manufacturing is compliant with

adjustments in design and particularization, giving the adaptability of a quick

transition by initiating a new tested and approved program. Returning to the

previous program anytime is also possible, with steady production of regular

quality in the emerging aluminum removal products.

Conclusion

Production of aluminum parts has been made

easier with the CNC machining process. The accuracy in extraction of such parts

is one reason the process is regarded as effective. You will get complex models

out of the CNC machining procedures. The simplicity and safety standards that

come with the procedure also makes it tick compared to the traditional manual

methods. How about you try the CNC machining process for the best and accurate

aluminum parts.

Comments

Post a Comment